“`html

How Digital Twins Revolutionize Manufacturing

Introduction

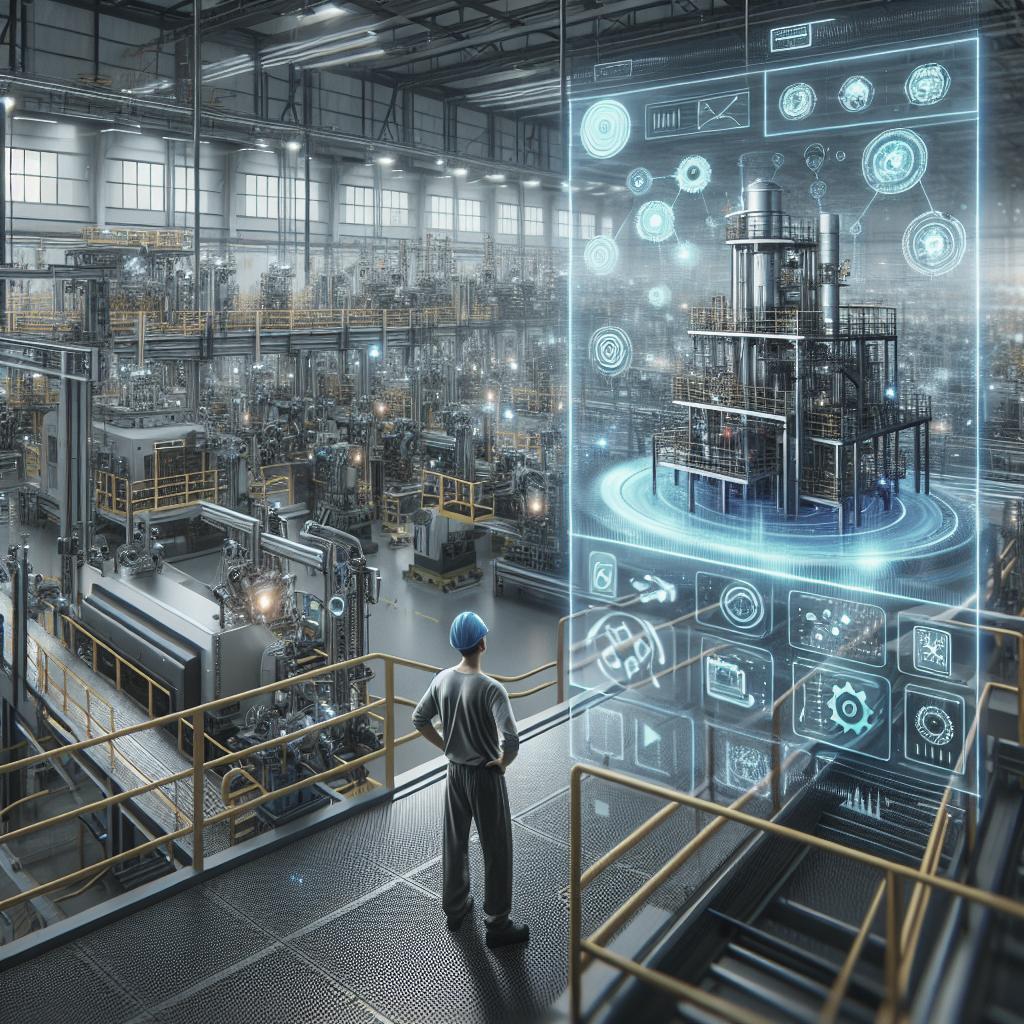

In the rapidly evolving world of manufacturing, digital twins have emerged as a game-changing innovation. These virtual replicas of physical assets allow manufacturers to analyze performance, optimize operations, and simulate various scenarios without the risks and costs associated with physical trials. This comprehensive guide delves into the concept of digital twins, tracing their historical context, exploring their integration with complementary technologies, and highlighting the myriad benefits they offer. By examining real-world use cases like equipment monitoring, training, and design planning, we’re uncovering how digital twins transform industry operations. Additionally, steps to create a digital twin for your facility provide practical insight into adopting this technology.

What is a Digital Twin in Manufacturing?

A digital twin in manufacturing is a virtual model that precisely replicates a physical object, process, or system. It allows manufacturers to simulate, analyze, and optimize across the lifecycle of a product, from design to deployment. By integrating real-world data, digital twins facilitate continuous feedback and adaptation, making processes more efficient.

This concept can be applied to various aspects such as machinery, entire production processes, or even complete factories. By mapping out the digital counterpart, manufacturers can test different parameters, predict failures, and devise strategies for performance enhancement without the cost or risk of doing so in the physical world.

Historical Context and Trends

The origin of digital twins can be traced back to NASA’s Apollo program, where simulations were used for space exploration missions. Today, advances in computational power, data analytics, and IoT have made digital twins more accessible and potent in the manufacturing sector. The need for increased operational efficiency and reduced downtime has fueled their proliferation.

Recent trends emphasize integrating digital twins with Industry 4.0 technologies like machine learning, artificial intelligence, and big data analytics. This amalgamation enables more profound insights and better decision-making capabilities, ensuring businesses maintain a competitive edge in a rapidly changing industrial landscape.

Complementary Technologies

Digital twins inherently rely on complementary technologies to realize their full potential. IoT provides the necessary connectivity, allowing real-time data collection from embedded sensors on physical assets. Through these advanced networks, digital twins gain access to continuous streams of data, offering timely insights.

Additionally, machine learning and artificial intelligence play a crucial role by analyzing collected data to unearth patterns, predict outcomes, and suggest improvements. When combined with virtual and augmented reality, digital twins offer an interactive visualization platform for stakeholders, enhancing understanding and collaboration in manufacturing environments.

Benefits of Using a Digital Twin

The advantages of employing digital twins in manufacturing are multifaceted. One of the most significant benefits is improved operational performance. By simulating various production processes and machine operations, manufacturers can pinpoint inefficiencies and optimize workflows without halting production.

Furthermore, digital twins offer predictive maintenance capabilities. By analyzing historical data and identifying trends, potential equipment failures can be detected before they occur, thus minimizing downtime and maintenance costs. This proactive approach extends the lifespan of machinery and contributes to significant cost savings.

Enhanced collaboration and innovation are also notable benefits. Digital twins offer a shared platform where teams can collaborate to design, test, and refine products or processes. This leads to accelerated innovation cycles, streamlined communication, and more agile responses to market changes.

Digital Twin Use Cases

Equipment Monitoring

In manufacturing, equipment monitoring is paramount. Digital twins facilitate this by providing real-time insights into machine health and performance. They track parameters such as temperature, vibration, and output rates, identifying deviations from normal operating conditions.

By continuously monitoring these metrics, digital twins enable prompt interventions before minor issues escalate into significant failures. This real-time vigilance reduces unexpected downtimes, maintains production flow, and enhances productivity.

Training

Digital twins revolutionize workforce training in manufacturing by offering immersive, risk-free environments for learning. Employees can engage with simulations that mimic real-world equipment and processes, gaining practical experience without any physical risks or interruptions to production.

Through interactive training modules powered by digital twins, operators and technicians get hands-on experience in tackling complex tasks, diagnosing problems, and understanding system intricacies, thereby improving skill levels and operational readiness.

Tours and Guests

The use of digital twins extends beyond operational facets to enhancement of tours and guest experiences in manufacturing facilities. Virtual tours can be created using digital twins, allowing visitors to explore production lines and processes without physical access.

This digital engagement is particularly beneficial for safety reasons, or when showcasing sensitive or proprietary technology to stakeholders in a controlled, secure manner. It provides an engaging overview without interference with everyday operations.

Design Planning

Design planning in manufacturing heavily benefits from digital twins. These virtual entities offer a sandbox for testing design changes, running simulations, and analyzing impacts without implementing them physically.

This ability to anticipate how modifications affect existing processes or systems outstrips traditional methods, leading to smarter decision-making, accelerated product development, and an overall reduction in time-to-market for new innovations.

How to Create a Digital Twin for Your Facility

1. Asset Selection

The first step in creating a digital twin for your facility involves selecting the asset you aim to replicate. It can range from a single piece of machinery to an entire production line. Prioritize assets that significantly impact your operations or those that suffer frequent downtimes.

Asset selection should align with your organizational goals, whether it’s improving productivity, reducing maintenance costs, or enhancing product quality. Involve cross-functional teams to determine which assets offer the most value when digitized.

2. Digital Representation Creation

Once assets are selected, creating their digital representation is essential. This involves constructing a detailed 3D model encompassing all components, structures, and functions. Using CAD software or digital modeling tools, build accurate virtual counterparts of the physical assets.

Ensure that these models are dynamic and can simulate different conditions and scenarios. Collaborate with engineering and design teams to maintain fidelity to the original assets, thus ensuring reliable simulations and analyses.

3. Sensor Integration and Data Collection

Integrating physical sensors and IoT devices with the assets is crucial for data collection. These devices monitor various parameters such as temperature, pressure, speed, and operational status, feeding real-time data into the digital twin.

Establish a robust IoT architecture to support seamless data flow between the physical and virtual worlds. Ensure the data is standardized and cleansed for precise and meaningful analyses, laying the groundwork for actionable insights.

4. Development of Analytical Models

With continuous data input, develop analytical models that process and interpret the information within the digital twin. Employ machine learning algorithms to predict outcomes, discover inefficiencies, and provide optimization suggestions.

These models need to continuously learn and adapt, ensuring they reflect the current state of operations closely. Collaborate with data scientists to create robust models, leveraging historical data to validate predictive accuracy and relevance.

5. Activation and Operational Integration

After developing the digital twin, integrate it with your day-to-day operations. Use it as a decision-support tool that provides real-time insights, guiding operational strategies, maintenance scheduling, and process evolution.

Train stakeholders on using the digital twin interface, highlighting its capacity to enhance performance and productivity. Ensure that it becomes an integral component of your operational strategy, fostering a culture of data-informed decision-making.

6. Continuous Improvement and Training

Post-implementation, focus on the continuous improvement of your digital twin. Regularly update it with new data, refine models, and incorporate user feedback to enhance accuracy and utility. Foster a loop of consistent learning and adaptation.

Additionally, use the digital twin framework for ongoing training opportunities for your workforce. As technology and operations evolve, ensure that your team is equipped with the latest knowledge and skills to keep pace with these changes.

Want to Learn More?

If you are interested in exploring further the transformative potential digital twins hold in the manufacturing sector, numerous resources are available. From case studies to webinars and expert articles, the body of knowledge continues to evolve. Engage with communities and forums as well to share experiences, challenges, and breakthroughs with peers.

For hands-on learning, consider partnering with technology providers specializing in digital twin implementations. Their guidance will help tailor solutions to your specific manufacturing needs, accelerating your journey towards digital transformation.

Latest from the Blog

Explore other trending topics and emerging technologies reshaping industries across the globe. Our blog features in-depth analyses, interviews, and expert opinions to keep you informed and inspired. Stay ahead of the curve and drive innovation in your domain.

Future Prospects

| Aspect | Summary |

|---|---|

| Definition | Virtual model of physical objects, processes, or systems for optimized manufacturing. |

| Historical Context | Originates from NASA’s Apollo program, now integrated with Industry 4.0 technologies. |

| Benefits | Improves operations, predictive maintenance, enhances collaboration, and drives innovation. |

| Use Cases | Equipment monitoring, training, tours, and design planning. |

| Creation Steps | Asset selection, digital creation, data integration, analytical model development, activation, continuous improvement. |

| Further Learning | Engage with resources, communities, and experts for deeper insights into digital twin implementation. |

“`